Equipment description

Equipment description

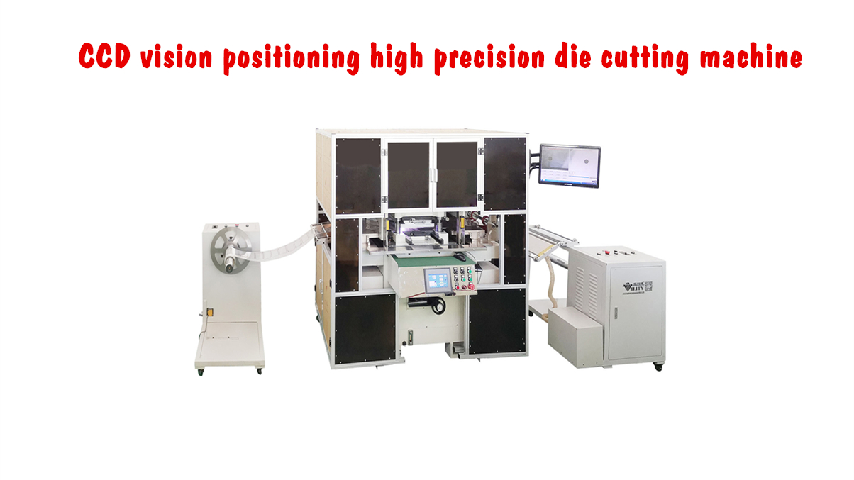

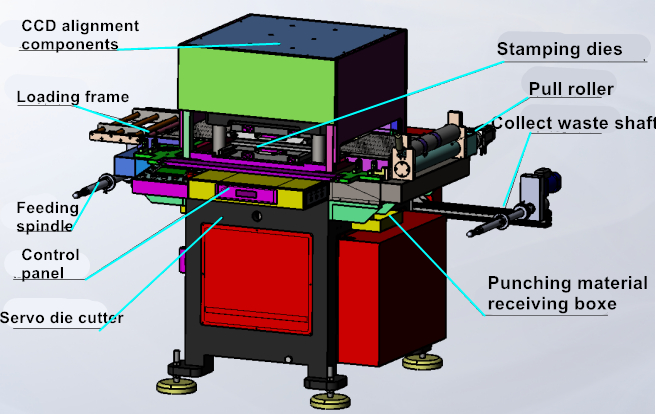

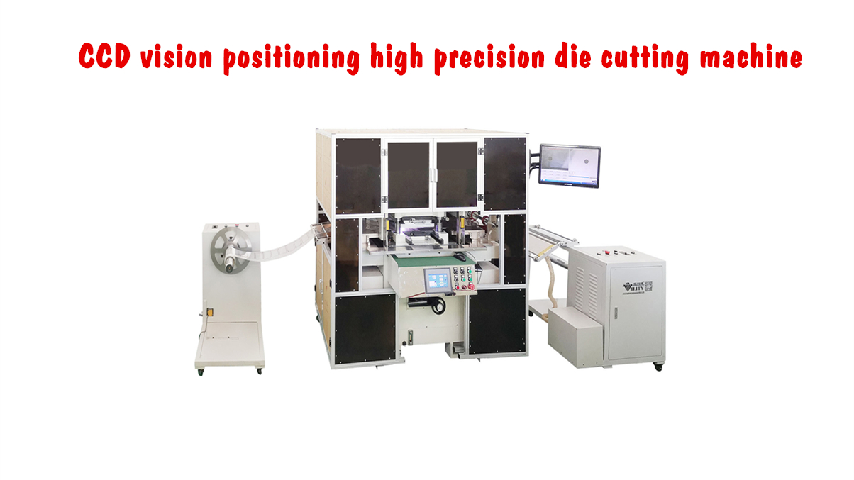

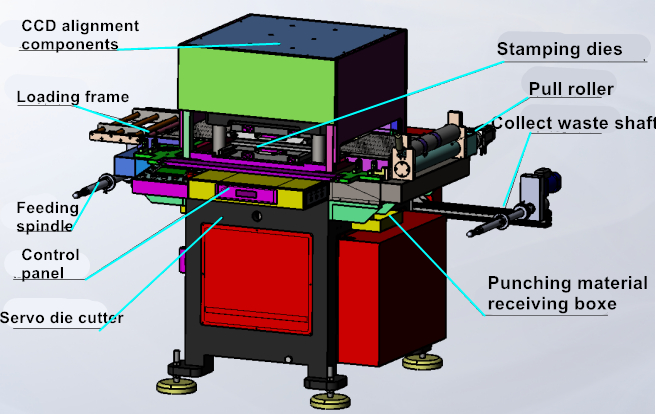

CCD roll-to-roll die-cutting machine is an automatic die-cutting equipment with high precision and high efficiency. Among them, the equipment mainly includes: CCD mobile platform, high-precision XYθ alignment platform, pulling mechanism, guiding mechanism, feeding mechanism, punching mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, etc., and separates the die-cut finished products and wastes according to the specified track. Once the equipment is adjusted, the machine will be completed automatically without any operation by personnel. The picture below is the machine design drawing and actual picture of the die-cutting machine.

Introduction to the important parts of the equipment

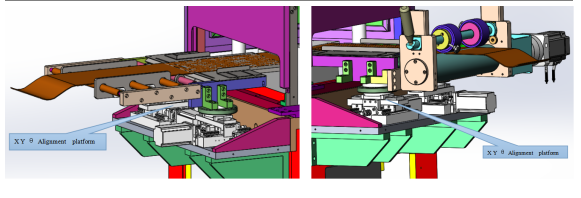

This equipment mainly includes a die-cutting unit. Both sides of the die-cutting unit are equipped with a CCD mobile platform, a high-precision XYθ alignment platform, and the alignment is stable and jitters are small. Human-machine interface control + button switch, various functional parameters can be set, and the operation is convenient. ; CCD automatic positioning and punching, can automatically adjust the CCD field of view according to the size of the material. The CCD automatically calculates the spatial position of the material and the mold according to the MARK point on the material, and instructs the motor to control the movement of the adjusting platform XYθ to rotate and automatically punch.

Features

Features

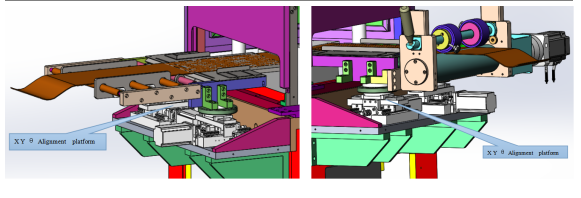

1. Alignment XYθ stage: Alignment XYθ stage is the core part of the machine and is used for CCD visual alignment. This alignment stage is composed of XYθ4 axes, with alignment eccentricity function, and the alignment accuracy can be controlled within 0.02mm.

2. Unwinding machine: The unwinding machine is used for the unwinding of the coil material. Every time the die-cutting machine is punched, the pulling roller will pull the jump distance of a product, and the unwinding machine will continue to unwind the material. Ensure punching efficiency.

3. Equipment Workflow

The discharge machine discharges the material, after the discharge is completed. CCD visual positioning detection, the error value of PET and positioning standard is sent to the industrial computer, and the industrial computer specifies the motor XYθ to move until the MARK point of the PET and the positioning standard are positioned according to the set accuracy, and the signal is sent to the die-cutting machine. Machine stamping. After the stamping is completed, enter the next cycle operation.

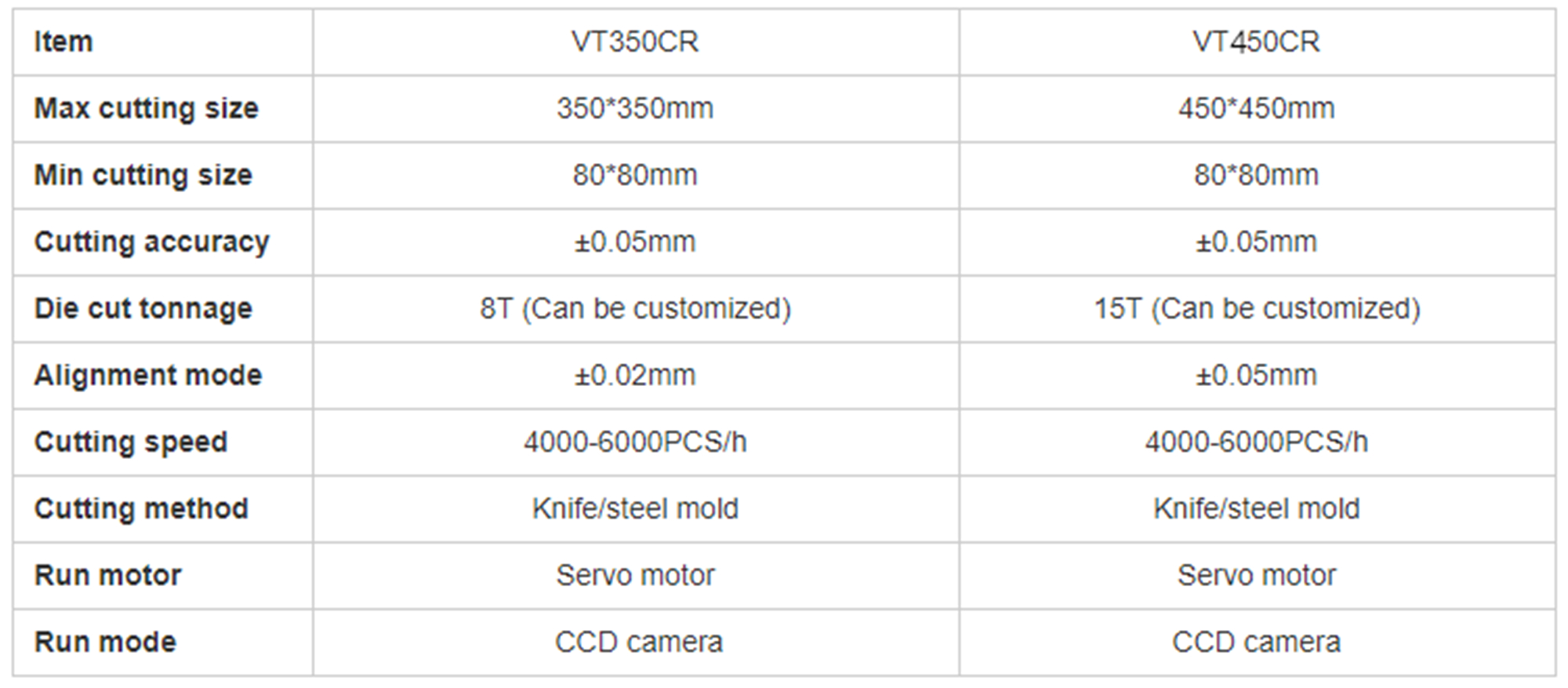

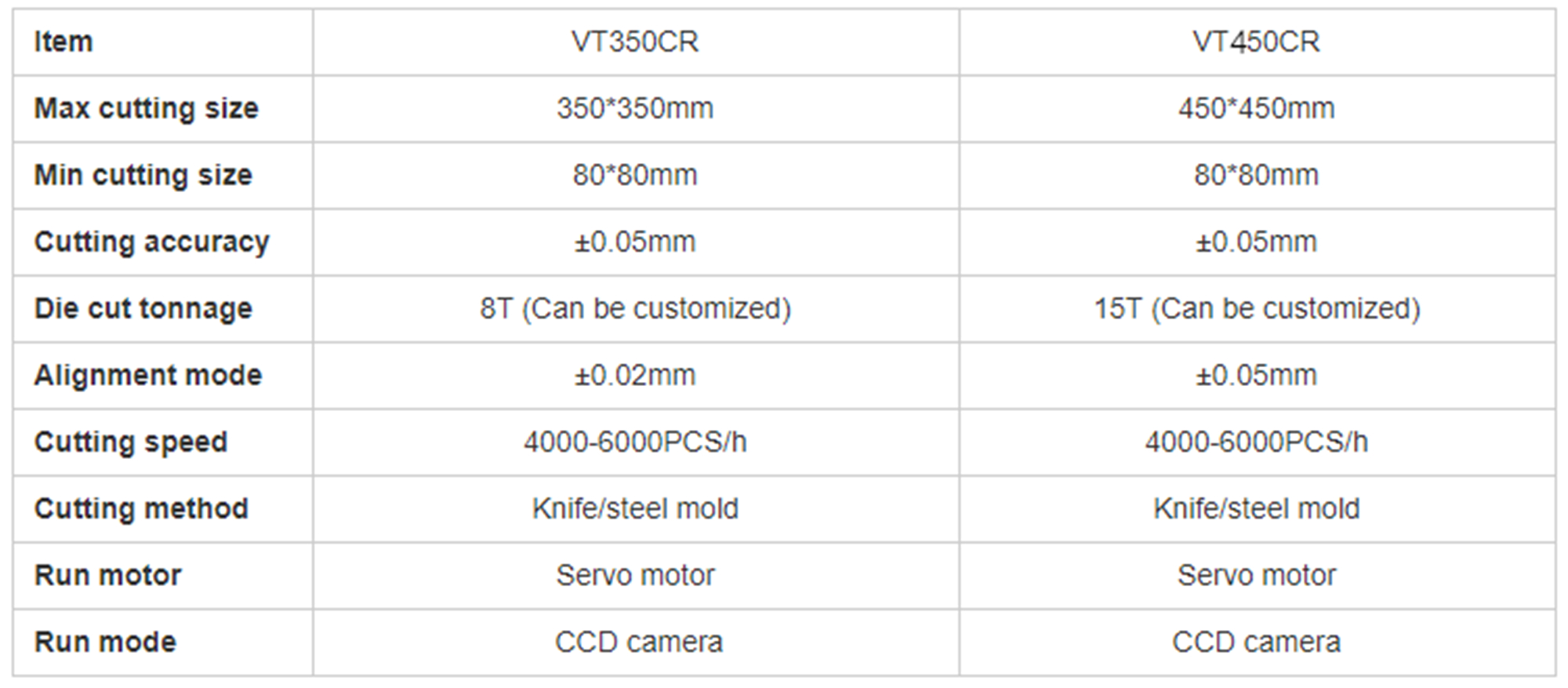

Parameters

Parameters

After-Sales Service

After-Sales Service

-

◪ We have a rich experience, technical good, service awareness ahead of the professional team, can be timely and effective solve the problem for you.

-

◪ Installation and debug machine for you without any charge. Also, giving a technical training for your employees.

-

◪ All of our machines can have one year guarantee and lifelong maintenance.

Contact Us:

Miya Xu, Whatsapp:+8615570070161

E-mail: Simon