Instant Registration on Printing

When printing, the screen is automatically registered to substrate in the meantime, time for initial printing to massive production is ≦5min, initial printing is eligible to save the waste material and raise high production efficiency, high printing accuracy and high production can be achieved synchronously.

4.Accept OEM/ODM, screen printing industry whole line customization.

1: Application Scope

This machine is widely used in FPC,PET, PVC, varies of label,transfer paper (film), floor heating film, geothermal film, electro thermal film, color paper, film, name plate, flexible circuit board, mobile phone keys, Membrane switch, trademark printing, scratch CARDS, self-adhesive stickers, paper, ribbon, aluminum foil and copper foil this roll material silk screen printing.

2: Features and performance

A: Main machine feature---screen printing machine

(1). CCD automatic alignment system, if the similarity is not within the setting range, any abnormal, it will stop and automatically start adjust the alignment successful and continue to work.

(2). Using numerical control motor, printing speed, return to the ink speed can be set in a random block.

(3). Using numerical control motor, printing distance, return to the ink distance can be set in a random data.

(4). Automatic computing printing, and calculate the qty, and printing can be set automatically stop.

(5). photoelectric control feeding and discharging to avoid the surface damage of substrates, can improve the printing quality.

B: The Feeder features:

(1). Photoelectric control feeding, avoid the surface damage of the material.

(2). Feeding speed, time, can adjust at will.

(3). The feeding starting speed, can adjust at will, start frequency starting from 0 up to run slowly, avoid the start too fast, cause the material surface scratches.

(4). Equipped with an automatic protective device.

| Name | Parameter | |

| CCD Printing machine | Working place area(mm) | 1000*660 |

| Max inputting width(mm) | 450 | |

| Max printing area(mm) | 600*450 | |

| Mix printing area(mm) | 400*500 | |

| Max size of screen frame(mm) | 1100*800 | |

| Mix size of screen frame(mm) | 300*200 | |

| printing thickness(mm) | 0.075-0.125 | |

| Mix print skip distance(mm) | 2 | |

| Working voltage (v) | 380-50Hz | |

| Maine machine Max power (kw) | 40 | |

| Working pressure(kg/cm2) | 5-8 | |

| Precision of printing(mm) | ±0.05 | |

| First printing speed | 1000-1200 times / hour | |

| Second printing speed | 800-1000 times/ hour | |

| Scraper stroke(mm) | 900 | |

| CCD precision | ±0.02 | |

| CCD center space | 330mm | |

| Main machine size (mm) | 3300*1600*2200 | |

| Receiving oven | Oven temperature(℃) | 0-190 |

| Oven working voltage(V) | 380 | |

| Oven max power (KW) | 24 | |

| Max size(mm) | 450 | |

| Oven size (mm) | L2400*W1200*H2100 | |

| Feeding goods max size(mm) | 450 | |

| Feeding machine | Feeder peak voltage(V) | 220 |

| POWER(KW) | 0.3 | |

| Size (mm) | 800*1000*1100 | |

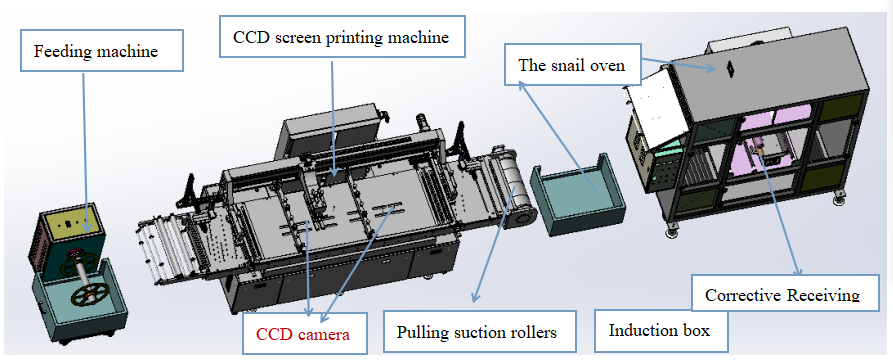

Machine Process

Raw material →Automatic feeding machine →Automatic printing→Automatic UV or oven →Automatic receiving →End product.

After-Sales Service

◪ We have a rich experience, technical good, service awareness ahead of the professional team, can be timely and effective solve the problem for you.

◪ Installation and debug machine for you without any charge. Also, giving a technical training for your employees.

◪ All of our machines can have one year guarantee and lifelong maintenance.

Contact Us:

Miya Xu, Whatsapp:+8615570070161

E-mail: Simon<simon@ccdmachine.com>

Address:2# 2 building Furong 7 Road, Xinqiao Furong industrial Park, Shajing Town, Baoan district, Shenzhen City, China.

Telephone: +8615570070161 Email:simon@ccdmachine.com QQ: 888888

Copyright:CopyRight © 2022-2027 Shenzhen Vility Automatic Machinery Co., Ltd 粤ICP备13083649号

Technical Support:YMB Software

威利特:公众号